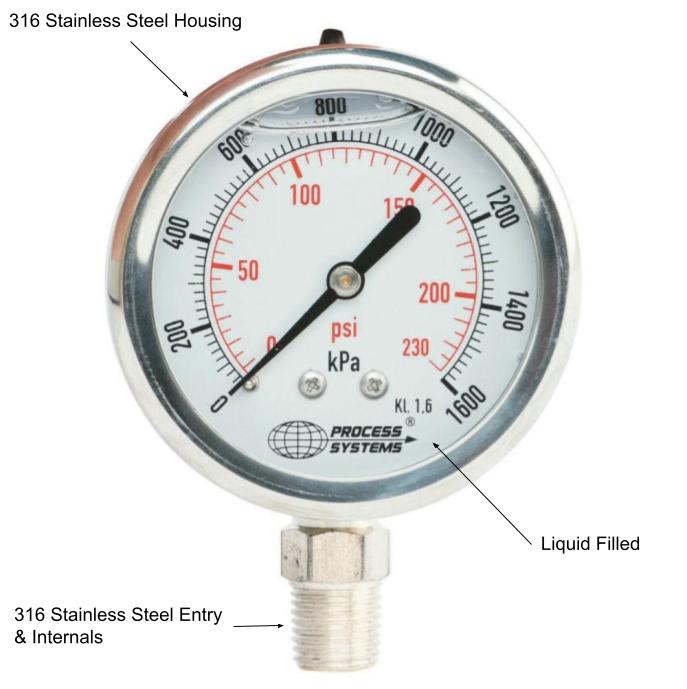

Features:

Pressure Range 0 kpa to 2500 kpa

Body Stainless Steel

Function Dual Scale Kpa/PSI glycerine filled pressure gauge

Connection 1/2" NPT Bottom Entry

Factory Accredited CE, ISO 9001, TUV

Full Stainless Steel 150mm glycerine filled pressure gauge with stainless steel internals and entry. Crimped ring housing with polycarbonate window. Dual scale kpa/psi. Accuracy +-1.0% of full scale. Operating temp of -20°C to 60°C. For use on compatable gases and liquids. Comes with back mounting flange.

| a | b | b1 | b2 | D1 | D2 | e | f | G | SW |

|---|---|---|---|---|---|---|---|---|---|

| 15.5 | 49.5 | 49.5 | 83 | 161 | 159 | 17.5 | 50 | 1/2" | 22 |

All dimensions in mm unless shown otherwise.

Pressure Range 0 kpa to 2500 kpa

Body Stainless Steel

Function Dual Scale Kpa/PSI glycerine filled pressure gauge

Connection 1/2" NPT Bottom Entry

Factory Accredited CE, ISO 9001, TUV

What is a 150mm Full Stainless Steel Liquid Filled Bottom Entry Pressure Gauge?

A Stainless Steel 150mm Liquid Filled Bottom Entry Pressure Gauge is a Pressure Gauge with a 150mm face on it (the face is what you can read). It is made out of 316 Stainless Steel housing, entry and internals and is filled with glycerine which is what we called liquid filled. The connection to the media or what we called entry is on the bottom of the pressure gauge. All liquid filled pressure gauges have an air bubble that you can see on the face, this just helps when the air pressure changes in the environment it wont force some of the liquid out of the dial.

How does a 150mm Full Stainless Steel Bottom Entry Pressure Gauge Work?

These pressure gauges utilise what is called a bourdon tube, this is simply a tube which deforms (or moves) as the media pressure changes. The other end is connected to the dial which will move with the change in media pressure giving you a reading of what it is. The gauge housing is liquid filled with glycerine which is great for industrial applications as it protects against vibration helping to eliminate what is called pointer flutter (where the dial is vibrating and not sitting on a constant pressure even though the media pressure is constant). It will also stop any condensation build up and help against corrosion inside the face of the dial. It is considered superior to a dry pressure gauge.

How do I choose the correct 150mm Full Stainless Steel Liquid Filled Bottom Entry Pressure Gauge?

The first step in choosing a pressure gauge is to decide whether you need bottom or rear entry. Bottom entry is more common however it cant be panel mounted like a rear entry gauge (the entry is behind the face of the dial for a rear entry, bottom entry is at the bottom of the gauge). The next step would be to decide your face size (how big you want the gauge to be to read) and the connection size, generally the bigger the dial the bigger the connection size to the media. Once these have been decided you will need to know what pressure range to choose. You must not only know the minimum and maximum pressure the gauge will see but also what the media pressure generally is. You want to choose this at about 3/4 scale on the pressure gauge. For instance if your pressure was 7 Bar you would most likely choose a 0 to 10 Bar pressure gauge as you will sit at 3/4 scale most of the time, or thereabouts.

How long will my 150mm Stainless Steel Liquid Filled Bottom Entry Pressure Gauge?

This really depends upon the conditions that the pressure gauge operates in and what the media is. If both the media and environment are clean the pressure gauge will last a very long time as it has few moving parts and is made of full 316 Stainless Steel including housing, entry and internals. In applications where the media is incompatible with the pressure gauge a diaphragm seal may be used which allows the media pressure to be read by the gauge but protects it from the media. If the temperature is too high for the pressure gauge, for instance if the media is steam, a pigtail syphon may be used which will protect the gauge against the higher media temperatures.

How do I install a 150mm Bottom Entry Pressure Gauge?

The first step is to isolate the media to the line and make sure there is no pressure present before installation, this is for user safety. Preferably the unit will be installed in an upright position with the bung facing up. This is to ensure that if the gauge needs to be zeroed to atmospheric pressure the bung can be opened without the liquid coming out. Also if there is a severe change in atmospheric pressure the bung may relieve the pressure itself so you wont have liquid leak out if it is facing upwards. However the pressure gauge will work in any orientation. Thread tape or thread sealant should be used on units with a tapered thread. Once the unit is installed properly line pressure can be resumed and the gauge checked. Also the bung on the top of the gauge should be opened and then closed, this will balance the pressure gauge to your local atmospheric pressure at that time.

What are typical uses of a 150mm Stainless Steel Liquid Filled Bottom Entry Pressure Gauge?

The pressure gauges are used on a wide variety of applications. They are very commonly used on water, compressed air, steam or any compatible media. As they are fully made of 316 Stainless Steel these usually are used in higher end applications or where the environment or media demand this material.

How do I maintain a 150mm Bottom Entry Pressure Full Stainless Steel Pressure Gauge?

There is very little maintenance involved with these pressure gauges. Apart from general cleaning of the face so it is free from dirt occasionally when the atmospheric pressure changes you can open the bung on the top of the gauge to reset the unit to the local atmospheric pressure. If there is a big change in pressure you may notice the gauge misreading, this will rectify this issue.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all Pressure Gauges leave our warehouse tested and inspected so there are rarely any issues. Also once your Gauge is in and operating it will most likely continue to do so for a very long time barring any external factors.

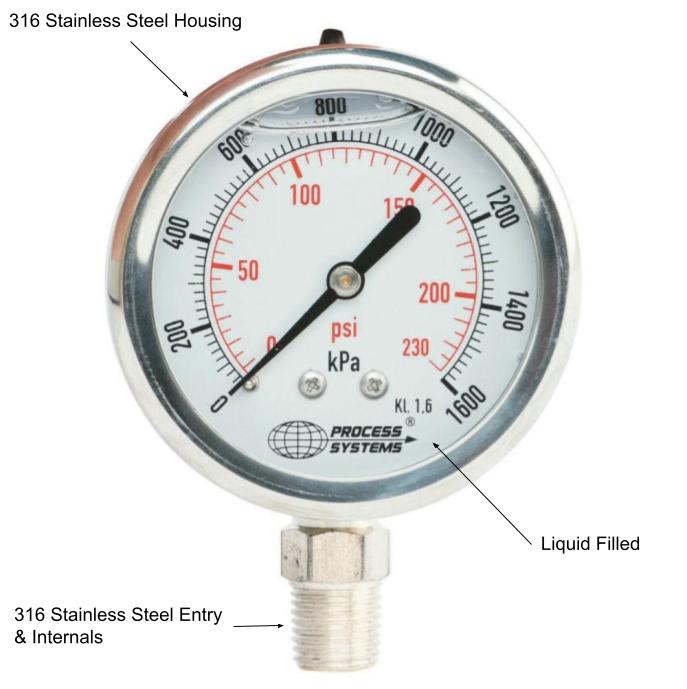

Pressure Range 0 kpa to 2500 kpa

Body Stainless Steel

Function Dual Scale Kpa/PSI glycerine filled pressure gauge

Connection 1/2" NPT Bottom Entry

Factory Accredited CE, ISO 9001, TUV

Full Stainless Steel 150mm glycerine filled pressure gauge with stainless steel internals and entry. Crimped ring housing with polycarbonate window. Dual scale kpa/psi. Accuracy +-1.0% of full scale. Operating temp of -20°C to 60°C. For use on compatable gases and liquids. Comes with back mounting flange.

| a | b | b1 | b2 | D1 | D2 | e | f | G | SW |

|---|---|---|---|---|---|---|---|---|---|

| 15.5 | 49.5 | 49.5 | 83 | 161 | 159 | 17.5 | 50 | 1/2" | 22 |

All dimensions in mm unless shown otherwise.

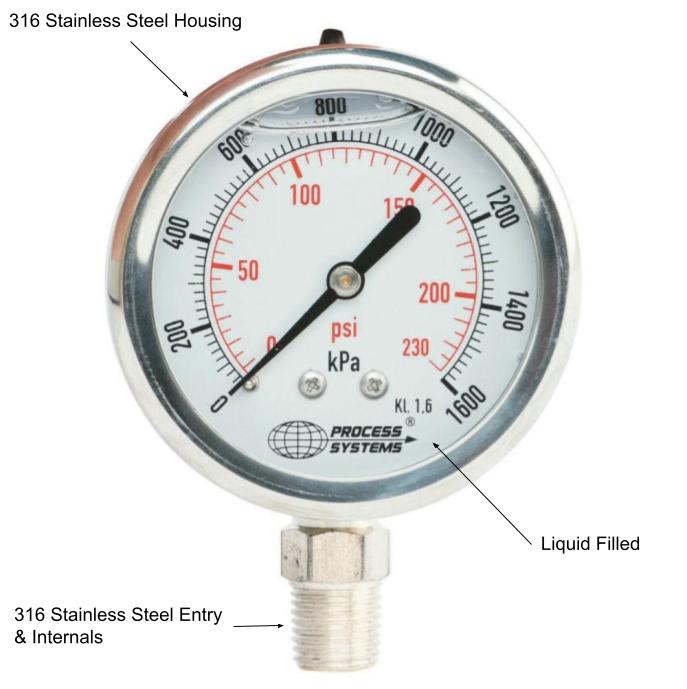

Pressure Range 0 kpa to 2500 kpa

Body Stainless Steel

Function Dual Scale Kpa/PSI glycerine filled pressure gauge

Connection 1/2" NPT Bottom Entry

Factory Accredited CE, ISO 9001, TUV

Full Stainless Steel 150mm glycerine filled pressure gauge with stainless steel internals and entry. Crimped ring housing with polycarbonate window. Dual scale kpa/psi. Accuracy +-1.0% of full scale. Operating temp of -20°C to 60°C. For use on compatable gases and liquids. Comes with back mounting flange.

| a | b | b1 | b2 | D1 | D2 | e | f | G | SW |

|---|---|---|---|---|---|---|---|---|---|

| 15.5 | 49.5 | 49.5 | 83 | 161 | 159 | 17.5 | 50 | 1/2" | 22 |

All dimensions in mm unless shown otherwise.