Features:

Size 1/2" to 2" BSP

Body 316 Stainless Steel

Pressure Range 0 to 7 BAR

Media Steam

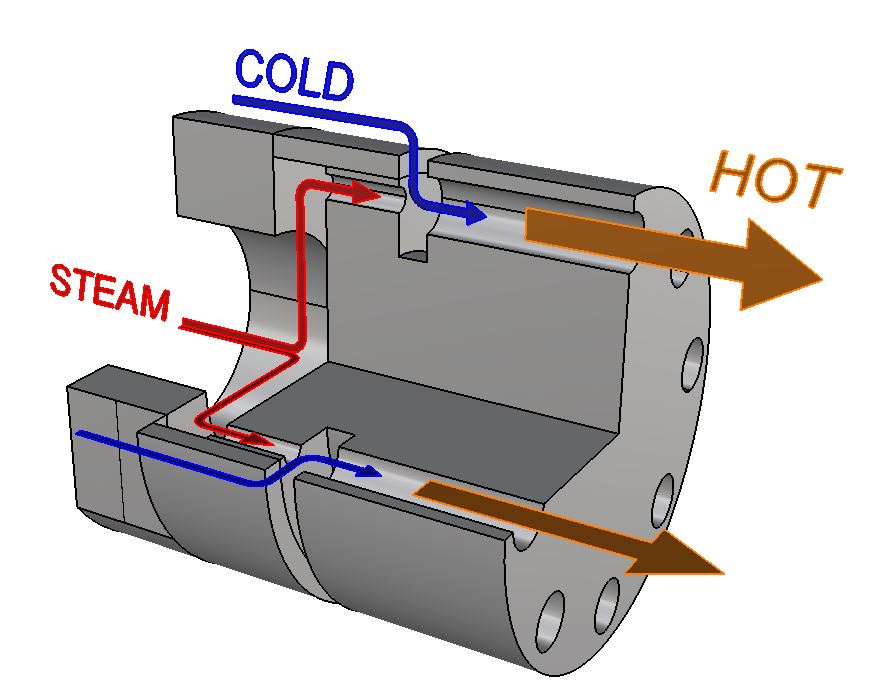

Noiseless heaters (silent water heaters) are used to reduce the noise created when steam is injected into a water tank to produce hot water. The manufactured shape of the Noisless heater draws the water around the heater through the side and mixes it with the steam flow to create and inject the heated water into the tank. The Noiseless heater features:

| Application | Steam |

|---|---|

| Type | Noiseless Heater / Vacuum Relief |

| Max Pressure | 7 Bar |

| Connection | BSPT (ISO7.1 Rc) |

| Body | Stainless Steel |

|

Capacity Chart

|

| Size | L (mm) | D (mm) | Weight (kg) |

|---|---|---|---|

| 1/2" BSPT | 48.5 | 35 | 0.25 |

| 3/4" BSPT | 49 | 45 | 0.4 |

| 1" BSPT | 52 | 50 | 0.52 |

| 1 1/4" BSPT | 55 | 60 | 0.77 |

| 1 1/2" BSPT | 59 | 70 | 1.15 |

| 2" BSPT | 65 | 105 | 2.99 |

Size 1/2" to 2" BSP

Body 316 Stainless Steel

Pressure Range 0 to 7 BAR

Media Steam

What is a Noiseless Heater/Steam Injector?

Direct steam injection heating systems are designed to inject steam directly into a product to be heated, usually tanks of water or process liquids. However if not designed and installed correctly, direct steam injection systems nearly always result in unacceptable noise and vibration. Historically, handmade sparge pipes were used to complete the task. Modern day technology has resulted in more compact, more efficient designs in various sizes that are easy to install and ensure quiet and efficient heating of the product. These are commonly reffered to as Noiselss Heaters, Steam Injectors or Silent Water Heaters (they are all the same thing).

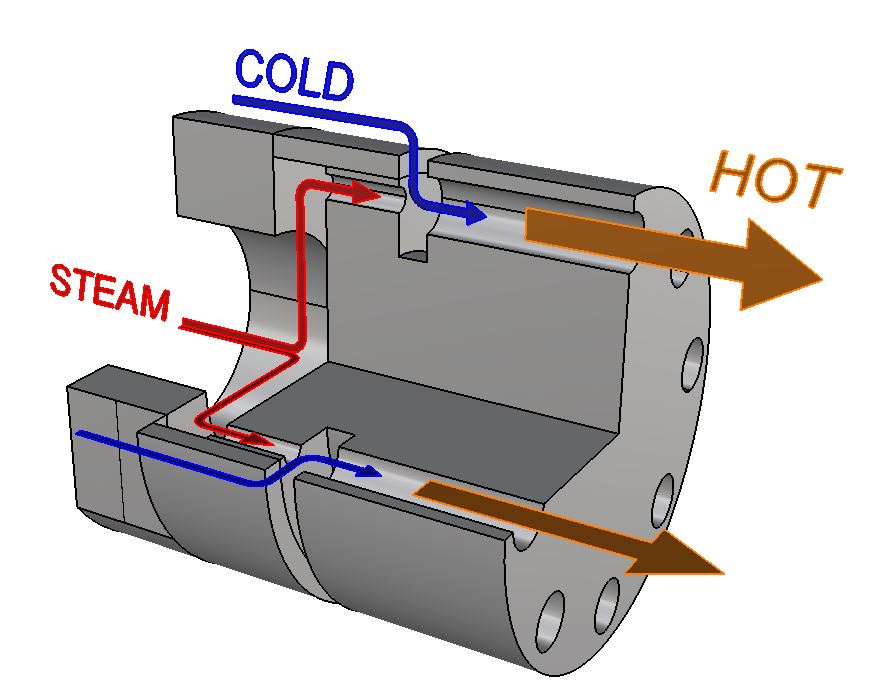

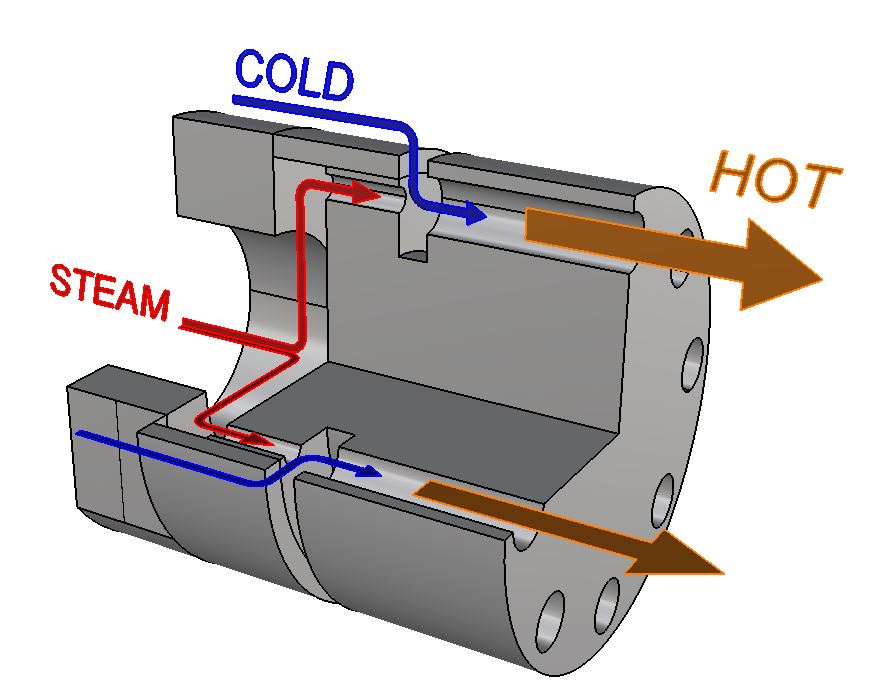

How does a Noiseless Heater work?

The noiseless heater uses the steam and its velocity to draw in cold product and mix it within the heater. This action results in product circulation. This is an advantage ensuring good mixing and helps to avoid temperature stratification. Direct steam injection, the simplest and most efficient way to provide hot water etc is by a direct heating format. The total heat energy (Total Enthalpy of Steam) is fully absorbed into the product being heated with no waste of available heat energy. It is important to remember that for every kilogram of steam used to heat up the product there will be 1 litre of water added to the product, so care must be taken to ensure there is enough room in the product heating tank to contain the extra fluid.

How long will my Steam Injector last?

This really depends upon the environment and the quality of the steam and fluids that the Noiseless Heater operates within. The installation of an upstream strainer is recommended to reduce the amount of dirt and other impurities from contaminating the internals. A correctly selected and sized Noiseless Heater with regular checks for correct operation, should perform for many years. Obviously it must be installed in accordance with the manufacturer's recommendations, maximum operating pressures must be adhered to. If during a check it is found to be faulty it should be cleaned or replaced as required. This will give the noiseless heater the best opportunity to continually operate satisfactorily for many years.

How do I install a Silend Water Heater?

To obtain the best results, ensure sizing is correct and maximum working pressures are adhered to, (0.05-0.7 MPa). While called a noiseless heater and they are extremely quiet in operation compared to other systems, It should be noted that if the installation is in an environment where any noise is a potential problem, care should be taken to use the available Noise Characteristic Chart to ensure noise is acceptable at the selected operating pressure as noise levels can vary in accordance with the rise and fall of the product temperatures and the nominal heater size. If in doubt, contact the supplier for guidance. When installing the noiseless heater it should be mounted well submerged in the product, while being 300mm or more from the tank’s walls and bottom. Simply screw the noiseless heater on to the end of a pipe, it can be mounted in the horizontal or vertical position. Always ensure that the noiseless heater and pipework is securely supported to prevent movement. Considered an integral part of any steam injection system, to avoid any reverse flow or suck back of product when the steam flow is stopped it is recommended that a Vacuum Breaker be installed prior to the noiseless heater.

What are typical uses of a Noiseless Heater?

Most commonly used as part of a temperature control solution for boiler feedwater tank heating, hot water heating and other industrial process heating applications. Applications where the use of live steam is suitable, and will not cause dilution, spillage or wastage due to any overflow, or contamination of product. A simple cost effective solution for the steam heating of water etc without the need for heat exchangers and steam traps etc.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all products leave our warehouse tested and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 1/2" to 2" BSP

Body 316 Stainless Steel

Pressure Range 0 to 7 BAR

Media Steam

Noiseless heaters (silent water heaters) are used to reduce the noise created when steam is injected into a water tank to produce hot water. The manufactured shape of the Noisless heater draws the water around the heater through the side and mixes it with the steam flow to create and inject the heated water into the tank. The Noiseless heater features:

| Application | Steam |

|---|---|

| Type | Noiseless Heater / Vacuum Relief |

| Max Pressure | 7 Bar |

| Connection | BSPT (ISO7.1 Rc) |

| Body | Stainless Steel |

|

Capacity Chart

|

| Size | L (mm) | D (mm) | Weight (kg) |

|---|---|---|---|

| 1/2" BSPT | 48.5 | 35 | 0.25 |

| 3/4" BSPT | 49 | 45 | 0.4 |

| 1" BSPT | 52 | 50 | 0.52 |

| 1 1/4" BSPT | 55 | 60 | 0.77 |

| 1 1/2" BSPT | 59 | 70 | 1.15 |

| 2" BSPT | 65 | 105 | 2.99 |

Size 1/2" to 2" BSP

Body 316 Stainless Steel

Pressure Range 0 to 7 BAR

Media Steam

Noiseless heaters (silent water heaters) are used to reduce the noise created when steam is injected into a water tank to produce hot water. The manufactured shape of the Noisless heater draws the water around the heater through the side and mixes it with the steam flow to create and inject the heated water into the tank. The Noiseless heater features:

| Application | Steam |

|---|---|

| Type | Noiseless Heater / Vacuum Relief |

| Max Pressure | 7 Bar |

| Connection | BSPT (ISO7.1 Rc) |

| Body | Stainless Steel |

|

Capacity Chart

|

| Size | L (mm) | D (mm) | Weight (kg) |

|---|---|---|---|

| 1/2" BSPT | 48.5 | 35 | 0.25 |

| 3/4" BSPT | 49 | 45 | 0.4 |

| 1" BSPT | 52 | 50 | 0.52 |

| 1 1/4" BSPT | 55 | 60 | 0.77 |

| 1 1/2" BSPT | 59 | 70 | 1.15 |

| 2" BSPT | 65 | 105 | 2.99 |