Features:

Size 50mm to 570mm

Body Anodised Aluminium

End Caps Epoxy coated aluminium

Pinion Nickel Plated Steel

Fixings 316 Stainless Steel

Actuation Spring Return Pneumatic

Incorporates the latest mechanical technology (rack and pinion design) to give long service life with light weight and high performance. The unit will spring back to its rest position in the absence of air making it great for fail safe applications. Features include end of stroke adjustment, visual Indicator, namur interface and ISO mounting interface. Options include IP67 limit switch box with visual Indicator, Namur (direct mount) solenoid valves and a range of inserts to step the drive down. These actuators can operate from -5°C to 80°C.

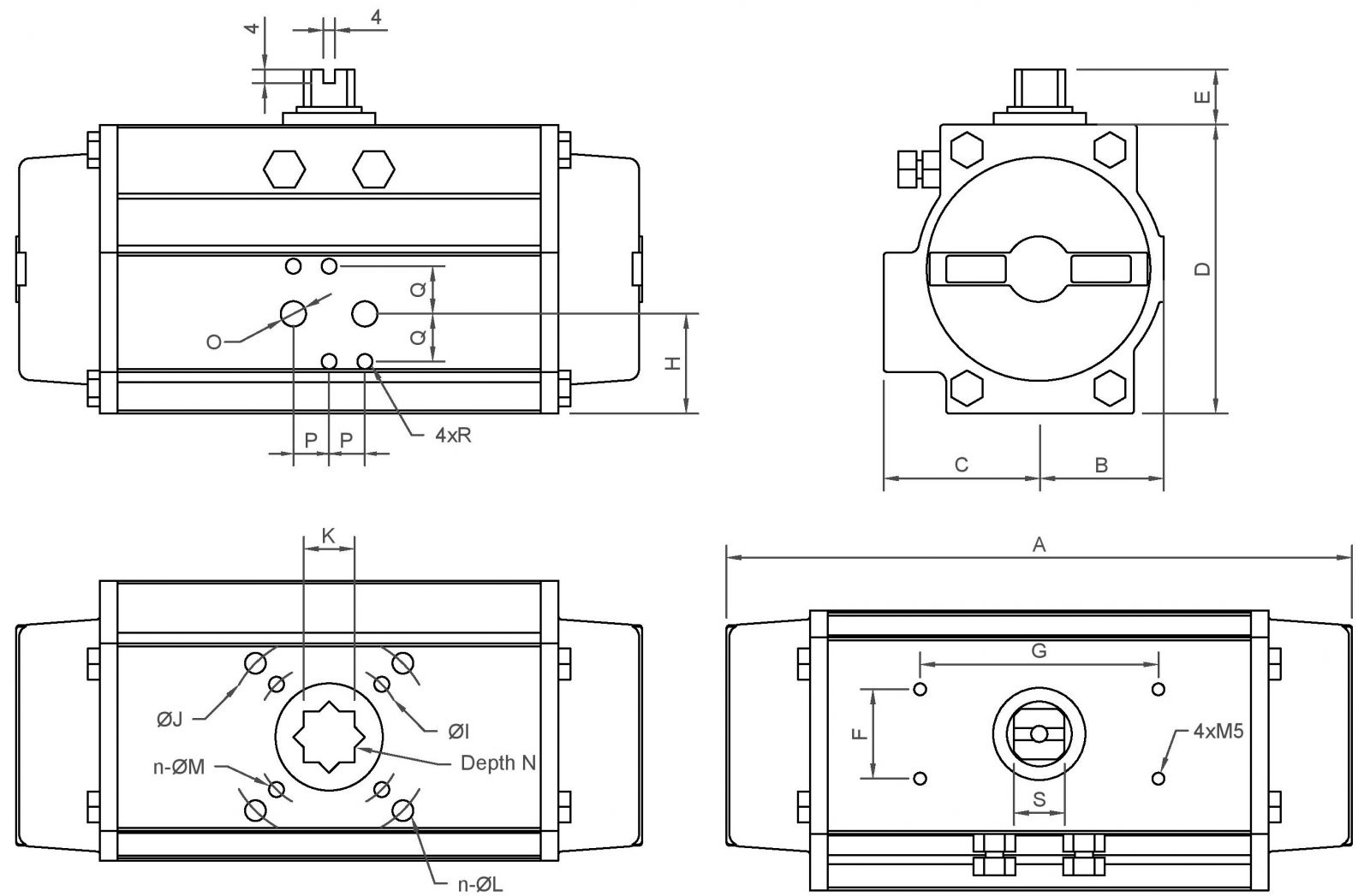

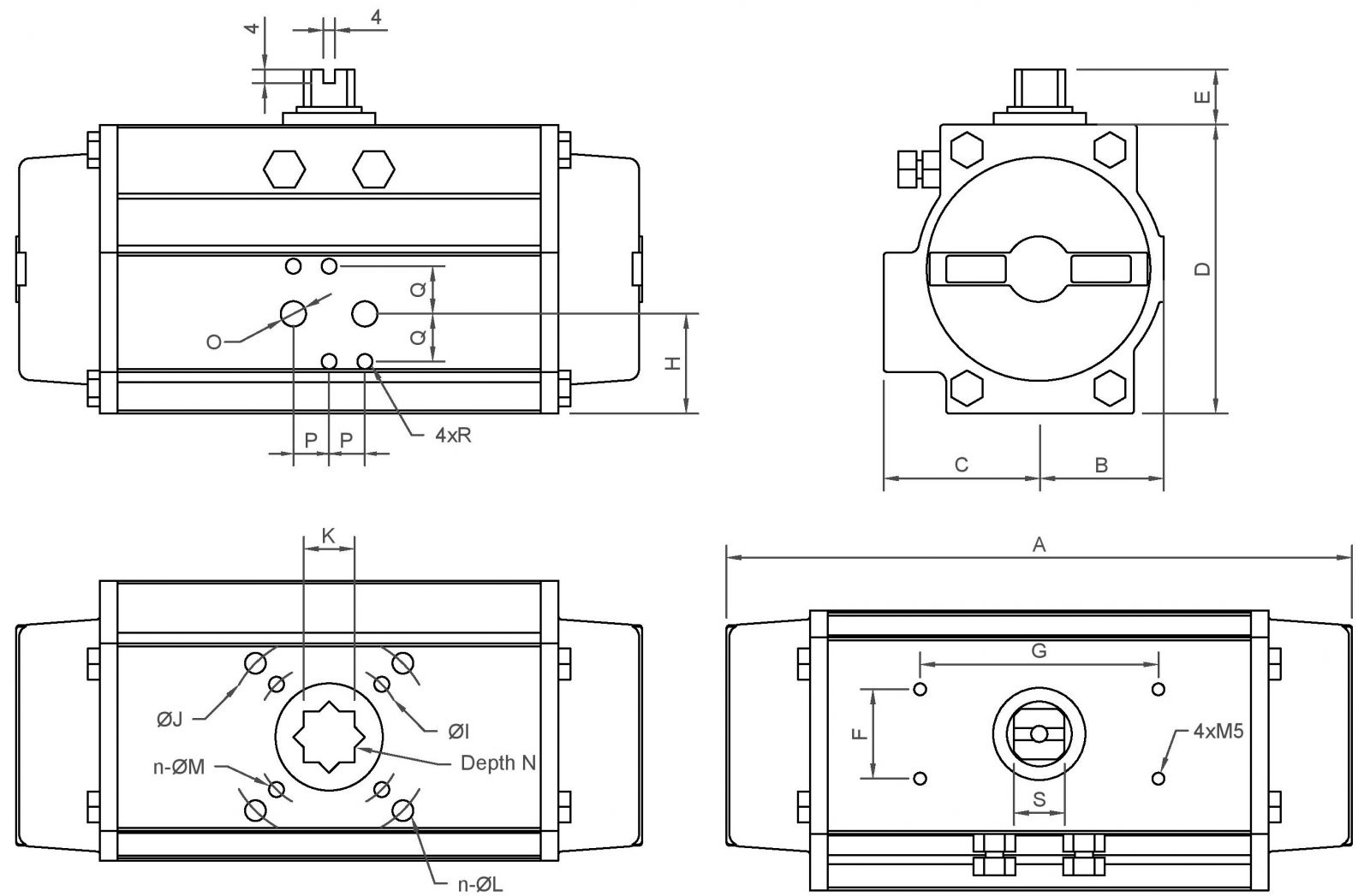

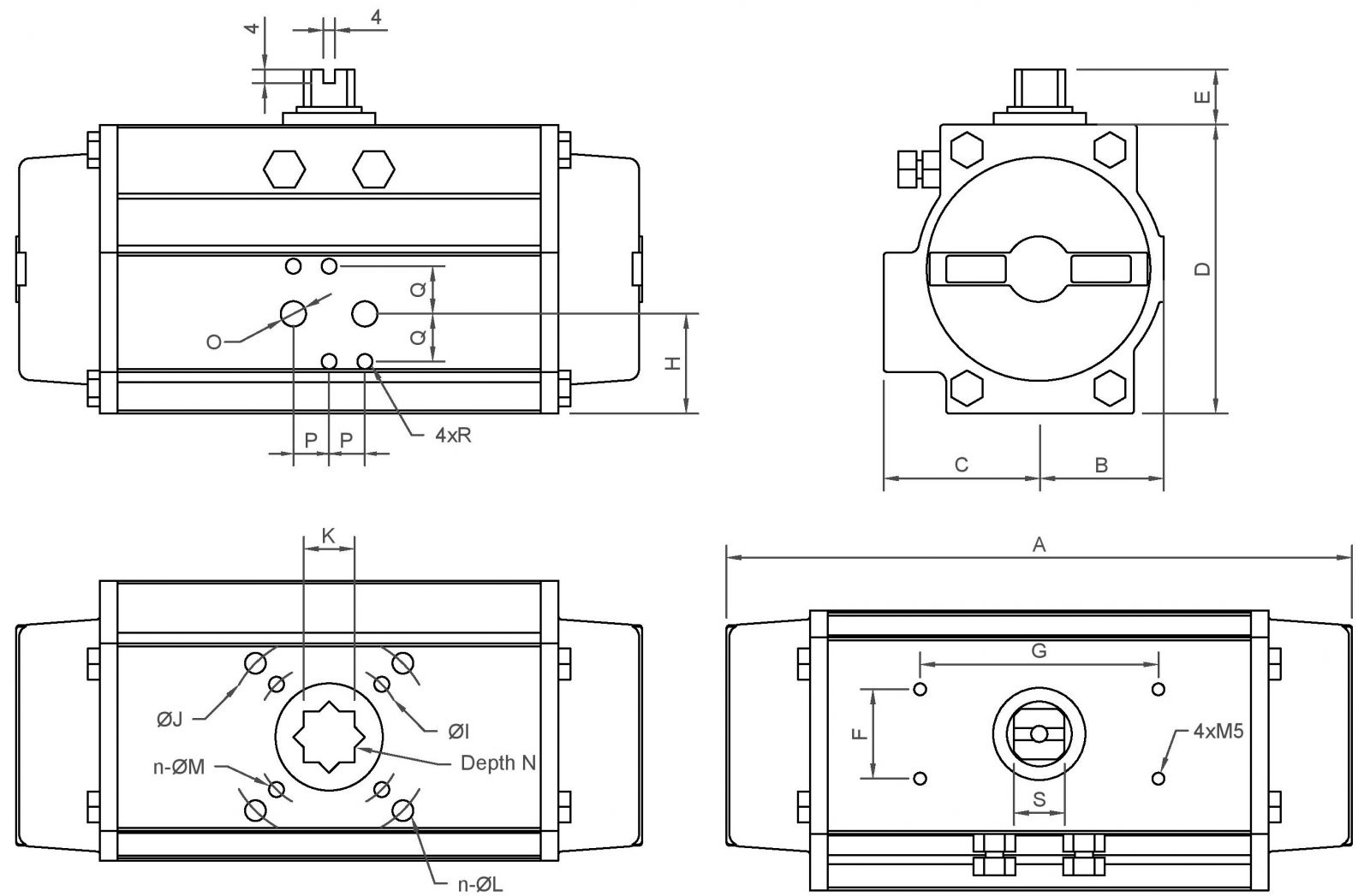

All dimensions in mm unless shown otherwise.

Size 50mm to 570mm

Body Anodised Aluminium

End Caps Epoxy coated aluminium

Pinion Nickel Plated Steel

Fixings 316 Stainless Steel

Actuation Spring Return Pneumatic

What is a Spring Return Rack & Pinion Pneumatic Actuator?

Spring Return (sometimes called Single Acting) Rack and Pinion Rotary Pneumatic Actuators are designed to turn ball, butterfly and plug valves through 90 degree rotation. Pneumatic air pressure is used to operate the actuator. The base of the pinion is attached to the valve stem. Single acting (Spring Return) function is achieved with internal preloaded spring sets acting on the end of the piston head. Pneumatic air pressure forces the racks in one direction and spring force closes them. This gives a fail safe function (Fail-Close or Fail Open) to the actuator when the pneumatic air pressure is removed. Spring Return actuators come in various sizes and corresponding torque ranges, with the torque increasing as the bore size increases (larger surface area of the piston).

How does a Spring Return Rack & Pinion Actuator work?

The Rack and Pinion are a pair of gears which convert linear motion into rotational motion. The rack with its piston head and seals engages teeth on the circular gear called the pinion giving rotational motion. The actuator uses two piston-type racks moving in opposite directions to give a balanced force on the central pinion. Pneumatic air pressure is used to operate the actuator. The base of the pinion is attached to the valve stem. Air pressure can be applied to open or close the valve with control over speed of rotation or force applied. As air pressure increases the force on the surface area of the piston is increased resulting in higher torque from the actuator. The Single acting (spring return) function is achieved with internal preloaded spring sets acting on the end of the piston head. Pneumatic air pressure forces the racks in one direction and spring force closes them. This gives a fail safe function (Fail-Close or Fail Open) to the actuator when the pneumatic air pressure is removed.

How do I size a Spring Return Actuator?

The spring return actuator sizing is based on the torque requirement for the valve to be actuated. From the valve data sheet obtain the Working Torque Nm (torque required to turn the valve at the required pressure, temperature and media viscosity) and add a minimum 30% safety factor. Always check breakaway- torque for the valve. Especially on butterfly valves this can be higher than the working torque because of the unseating of the valve disc off the seats. Using this figure find the corresponding single acting (spring return) actuator with this torque figure (or greater) and select. Also check the valve mounting pad configuration against the valve hole pattern. It may be necessary to step up an actuator size to accommodate ease of mounting. For air operation use the torque figure that relates to the air pressure available (which should be between 6-8 Bar). With the spring close use the torque figure shown under action of the springs (the torque figure when the springs are fully extended). This will ensure that the actuator will close the valve without any air pressure (fail safe).

How long will my Spring Return Air Actuator Last?

Like any valve this depends upon the usage case of your single acting actuator, its environment, media and how many times it is cycled. These are available as spare parts in a repair kit. The actuators life will depend upon how clean and dry the supply air is (the air that makes the actuator operate) however we regularly test these to over 800,000 cycles. Install a basic air filter if you are not sure about the quality of your air, we have pneumatic actuators that have been in operation for decades. The most common failure we see is due to dirty wet air used in the actuator. A FRL unit in the air supply will help with contaminated air. For Spring Return actuators we recommend running air to both sides of the piston in the same way you would for a double acting. This ensures that clean air is only entering your actuator otherwise in a single acting function air from the atmosphere will enter your actuator when it returns under spring pressure only. The easiest way to do this is to use a 5/2 namur valve.

How do I install a Spring Return Pneumatic Actuator?

The SR actuator can be installed either by direct mounting (ours have an ISO 5211 compatible mounting interface) or via an adaptor to any ball, butterfly or plug valve that requires a 90 degree rotation. The actuator can be mounted in any position and tolerate most environments. If the valve does not have the ISO 5211 mounting pad an adaptor can be customized to fit. Star drive and square sleeve adaptors can also be supplied to accommodate various stems. Namur valves directly interface onto the actuator for control and feedback can be achieved by mounting a suitable limit switch box directly onto the ISO indicator area.Speed of rotation can be controlled with precision using inline or exhaust speed controllers. Been spring return you should have the valve in the fail safe position you want it to fail to (eg. open or closed) and the put the actuator on with no air. This will set it up to fail to that position.

What are typical uses of a Rack & Pinion Spring Return Pneumatic Actuator?

Applying rotational control through 90 degrees the spring return pneumatic actuator can operate ball, butterfly and plug valves in many sizes. There are many uses outside actuating a valve and we have even seen our actuators used on sheep gates. Pneumatic actuators use compressed air giving reliability in difficult environments, explosive atmospheres and where electrically cannot be supplied. Been spring return it is commonly used in applications where a fail safe postion is needed (eg. fail close or fail open).

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all actuators leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time barring any debris getting caught in the valve or power spikes causing the coil to fail..

Size 50mm to 570mm

Body Anodised Aluminium

End Caps Epoxy coated aluminium

Pinion Nickel Plated Steel

Fixings 316 Stainless Steel

Actuation Spring Return Pneumatic

Incorporates the latest mechanical technology (rack and pinion design) to give long service life with light weight and high performance. The unit will spring back to its rest position in the absence of air making it great for fail safe applications. Features include end of stroke adjustment, visual Indicator, namur interface and ISO mounting interface. Options include IP67 limit switch box with visual Indicator, Namur (direct mount) solenoid valves and a range of inserts to step the drive down. These actuators can operate from -5°C to 80°C.

All dimensions in mm unless shown otherwise.

Size 50mm to 570mm

Body Anodised Aluminium

End Caps Epoxy coated aluminium

Pinion Nickel Plated Steel

Fixings 316 Stainless Steel

Actuation Spring Return Pneumatic

Incorporates the latest mechanical technology (rack and pinion design) to give long service life with light weight and high performance. The unit will spring back to its rest position in the absence of air making it great for fail safe applications. Features include end of stroke adjustment, visual Indicator, namur interface and ISO mounting interface. Options include IP67 limit switch box with visual Indicator, Namur (direct mount) solenoid valves and a range of inserts to step the drive down. These actuators can operate from -5°C to 80°C.

All dimensions in mm unless shown otherwise.