Features:

Size 1/4" to 4" BSP

Body 316 Stainless Steel 2 piece

Seat RPTFE

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

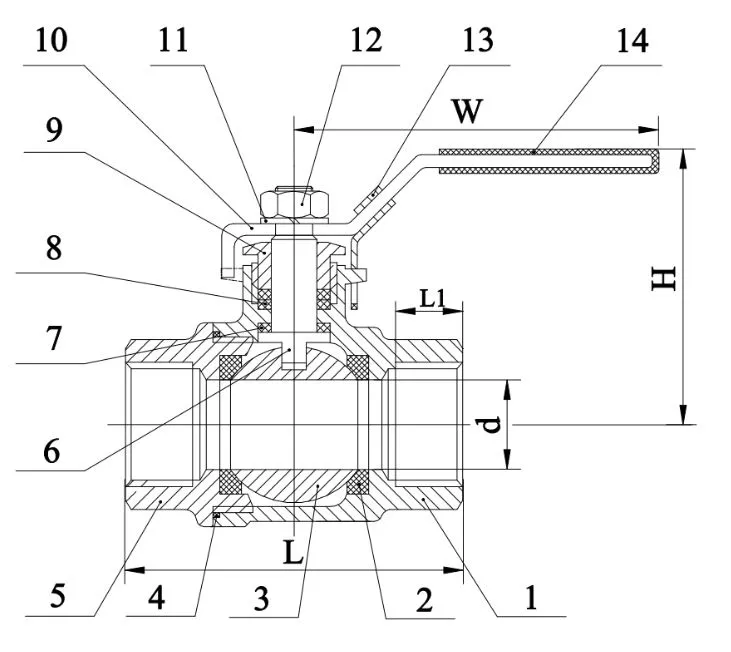

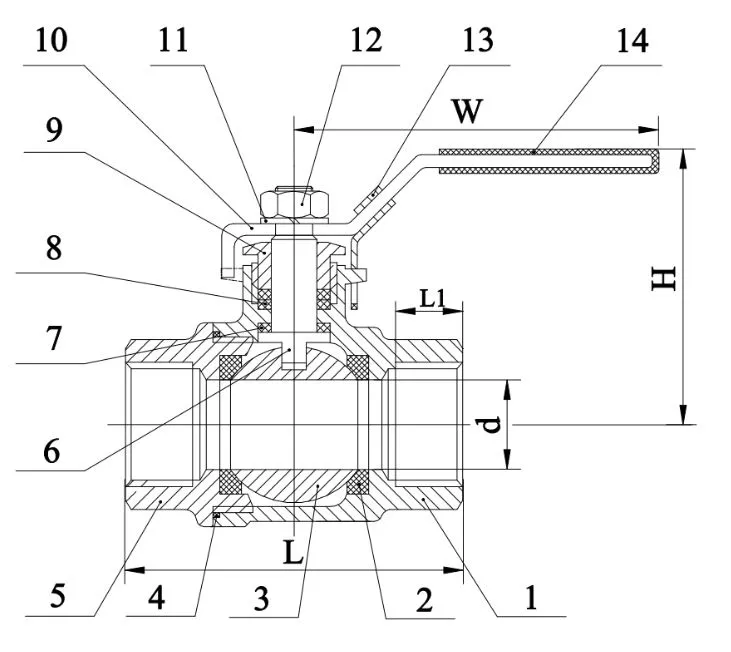

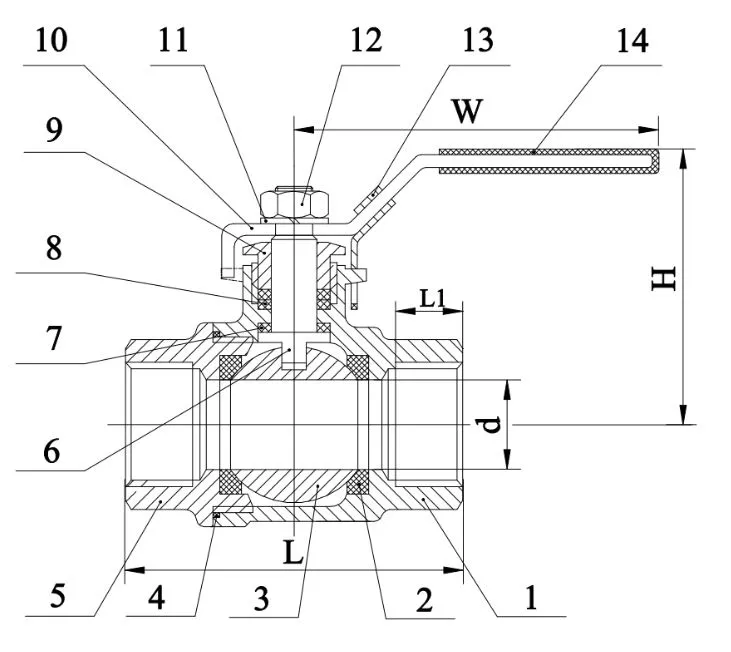

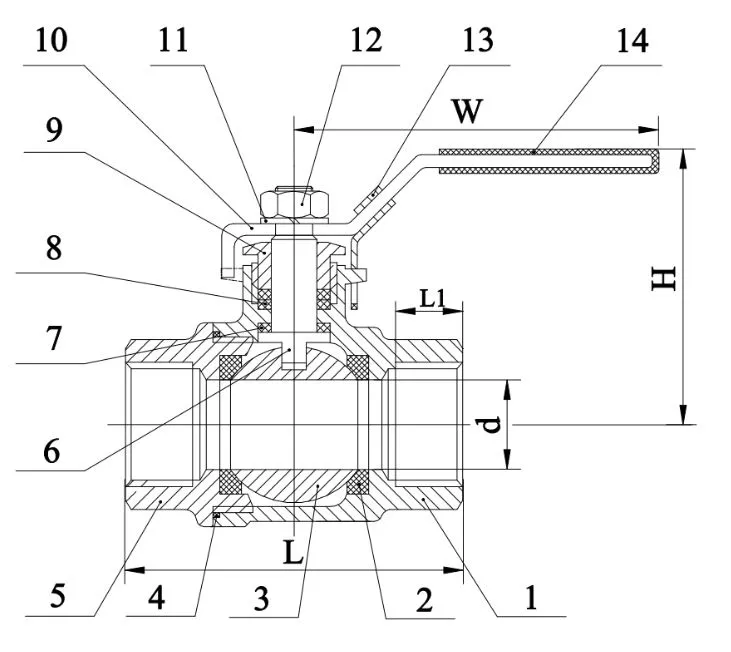

Robust 316 Stainless Steel Full Bore Two way two piece manual ball valve. With a RPTFE seat, 304 SS handle and full ISO thread lengths makes it suitable for a range of uses including general industrial with maximum pleak temperatures up to 180°C (please note for Australian Gas Association Approval (AGA) the maxiumum approved operating temperature is 80°C). This lever operation on this ball valve is lockable so it can be fixed in one position. Threads conform to ISO 7.1 Sealing Threads. Watermark Approved (License Number WMK26528) approved to AS 5830.1-2012.

All dimensions in mm unless shown otherwise.

Size 1/4" to 4" BSP

Body 316 Stainless Steel 2 piece

Seat RPTFE

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

What is a Two Piece Stainless Steel Ball Valve?

A Two Piece Stainless Steel Ball Valve is made of two 316 Stainless Steel Body Pieces that house the rotating ball inside it. These are two way units with a female port at either end. The Ball Valve is operated by rotating the Stainless Steel Handle 90 degrees which will open or close the ball valve. The handle is stopped at these positions by a limit stop which is cast into the body of the valve, this will stop the user moving the ball past the fully closed and fully open point.

How does a Two Piece Stainless Steel Ball Valve Work?

Housed within the body of the ball valve is a polished 316 Stainless Steel Ball. This has a hole at either end which is equal to the inside diameter of the valve. When rotated 90 degrees it will either expose these holes to the flow or close them off from the flow allowing the valve to close or open. The ball is turned by a shaft which connects to a handle on the top of the valve. This type of Ball Valve is often called a floating ball valve as the ball itself is suspended within the cavity of the ball valve with the PTFE seats holding the ball from either end of the valve (and also sealing it).

What are Typical Uses of a Two Piece Stainless Steel Ball Valve?

These two piece Stainless Steel Ball Valves are commonly used as an Isolation Valve. As they are watermark approved they are also used on a lot of potable water applications such as isolating water feeds and fire systems. Really they can be used in any application where the media, temperature and pressure fit within the scope of the ball valve. As they are all made of 316 Stainless Steel including the handle (many valves only have plated steel handles) they are also used frequently in corrosive environments.

How do I install a Two Piece Stainless Steel Ball Valve?

These are very easy to install as they are bi-directional meaning they do not have a direction of flow (unlike a solenoid valve for instance). Ensure the line is isolated and with no pressure if installing into an existing line. This model has female threaded ends so a male nipple or thread will need to be inserted into the valve. They are designed to achieve a thread seal (the female is parallel so the male nipple should be tapered) and ensure that this has appropriate thread sealant or tape to achieve a bubble tight seal. They can be installed on any axis and any way if needed. Once installed slowly bring the line up to operating pressure and check for leaks around the valve. If you are unsure if your threads are sealed and the medium is a gas, soapy water can be sprayed on the ends to check for any bubbles. The installer is not required to make any adjustments to the valve itself as they come pressure and cycle tested allowing for a simple install.

How do I Maintain a Two Piece Stainless Steel Ball Valve?

There is essentially no maintenance required on these ball valves except for a routine visual inspection to ensure the valve is sealing. As it is used as an isolation valve it should also be checked on your routine maintenance schedule that the valve is still isolating. This can be done either visually if you can see or hear the outlet after the valve or by using a downstream pressure gauge to ensure no media is passing. The valve itself uses a body gasket so the two pieces can be removed from each other to inspect the inside of the valve including the ball and seats. However due to the price users find it more economical to replace a worn valve than do an overhaul. The stem does utilise a gland seal to form a bubble tight seal between the body and the shaft. If the valve has a high cycle rate occasionally the gland may need to be tightened if it is weeping. This is performed by removing the handle and tightening the gland nut underneath it. The handle can then be put back on and the valve operated.

How do I Troubleshoot a Two Piece Stainless Steel Ball Valve?

Problems are very rare with these ball valves as all come fully cycle and pressure tested. Usually a problem stems from either an issue with the install or an external factor such as debris in the line. The most common would be where not enough thread tape or thread sealant has been applied during install and the male nipples at each end do not seal on the thread properly. This can easily be corrected by removing and placing more tape or sealant on the threads. Apart from this over the life of the valve if the cycle rate is high that the media can weep from the gland seal on top of the valve. This can be solved by removing the handle and tightening the gland nut underneath. There is a full troubleshooting guide on manual ball valves found under this link.

How long will my Two Piece Stainless Steel Ball Valve Last?

This really depends upon the environment and media that the ball valve is exposed to. The cycle rate will feature heavily as well as if the valve is only cycled once a day it may well last over a decade however if it is cycled frequently it will wear out sooner. We lab test these to 30,000 cycles and they still hold a bubble tight seal. They do feature a reinforced teflon seat here where as most valves just use a virgin ptfe seat. The reinforced seat allows the valve to do a higher pressure, temperature and ultimately lasts longer.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. These are quality industrial valves that hold multiple certifications and are built & certified to the highest standards and each batch has material and testing certificates. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 1/4" to 4" BSP

Body 316 Stainless Steel 2 piece

Seat RPTFE

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

Robust 316 Stainless Steel Full Bore Two way two piece manual ball valve. With a RPTFE seat, 304 SS handle and full ISO thread lengths makes it suitable for a range of uses including general industrial with maximum pleak temperatures up to 180°C (please note for Australian Gas Association Approval (AGA) the maxiumum approved operating temperature is 80°C). This lever operation on this ball valve is lockable so it can be fixed in one position. Threads conform to ISO 7.1 Sealing Threads. Watermark Approved (License Number WMK26528) approved to AS 5830.1-2012.

All dimensions in mm unless shown otherwise.